Quality Manual

Quality Manual

Prepared in compliance with ISO 9001:2008|

Address: Jiedong Road xiaojiejiao District, Humen town, Dongguan city, Guangdong province, China. |

|

Table of Contents

| Section | Title |

| Revision History | |

| Scope | |

| Quality Policy | |

| Quality Management System Process Interface Diagram | |

|

|

Revision History

| Revision Date |

Nature of Change(s)

|

| 8/2/04 |

|

| 11/3/04 |

|

| 11/16/07 |

|

| 10/12/08 |

|

| 11/12/08 |

|

| 3/2/09 |

|

| 10/30/09 |

|

Scope

The Quality Management System described and referenced by this manual applies to:

Longterm link:

Jiedong Road, Xiaojiejiao District,

Humen town, Dongguan city, Guangdong province, China.

The manufacturer of customer-designed wire formed products, and related products and assemblies for the electronics, automotive, appliance and other consumer products industries.

Longterm link follows all requirements of the ISO 9001:2008 standard excluding those requirements listed under section 7.3 Design and Development.

Quality Policy

Longterm link’s Quality Policy is to comply with the requirements and continually improve the effectiveness of our quality management system in order to provide our customers a quality product on time.

QMS Process Interface Diagram

QMS Process Descriptions

| Management Process | |||||

|

Previous Process Contact |

Inputs | Description of Key Activities | Output | Subsequent Process / Contact | |

| Internal | management goals |

· communicate to employees the importance of meeting customer as well as statutory and regulatory requirements, if any · establish quality policy – reviewed in Management Review Meetings · establish quality objectives · define responsibilities and authorities and assure these are communicated · assignment of QMS Management Representative |

· determine and provide resources · provide training and maintain Competence Matrices · review of QMS at least 1/calendar year (see Management Review Agenda) · monitor processes and analyze data in accordance with the Monitoring and Analysis Summary · manage internal audits · manage corrective and preventive actions |

effective processes | all processes |

| data from other processes | continual improvement | ||||

| QMS requirements | customer satisfaction | customer | |||

| External | customer / marketplace input | ||||

|

Related Procedures: · Document and Data Control Procedure · Quality Records Procedure |

· Periodic Management Review Agenda · Calibration and Control of Measuring and Test Equipment Procedure |

· Employee Competency Procedure · Internal Quality Audits Procedure · Corrective / Preventive Action Procedure |

|||

| Quotation Process | |||||

| Previous Process / Contact | Inputs | Description of Key Activities | Output | Subsequent Process / Contact | |

| customer | request for quote (includes drawings and/or specs) |

· print review · tool review · feasibility determination |

· determine cost · lead-time |

quote | customer |

| Order Handling Process | |||||

| revision changes | drawings and specs | Order Handling Process | |||

| Purchasing Process | price changes | ||||

|

Related Procedures: · Quotations to Customers Procedure |

· Customer Prints Procedure |

||||

| Order Handling Process | |||||

| Previous Process / Contact | Inputs | Description of Key Activities | Outputs | Subsequent Process / Contact | |

| customer | order |

· review order · enter order in system · acknowledge order when requested |

· maintain record of communication with customer if customer property is lost or found damaged or unsuitable for use | order entered | Purchasing Process |

| Quotation Process | quote, drawings, specs | Production Process | |||

| Shipping Process | |||||

| drawings, specs | Production Process | ||||

| Purchasing Process | |||||

| Sales Order | Shipping Process | ||||

| order acknowledgement | customer | ||||

|

Related Procedures: · Customer Orders Procedure |

|||||

| Purchasing Process | |||||

| Previous Process / Contact | Inputs | Description of Key Activities | Outputs | Subsequent Process / Contact | |

| Order Handling Process | order, drawings, specs |

· select suppliers · review Wire Needed Report · submit POs |

· receive product · evaluate suppliers |

material available for production and shipping | Production and Shipping Processes |

|

Related Procedures: · Purchasing Procedure |

· Supplier Evaluation Procedure |

· Receiving Work Instructions |

|||

| Production Process | |||||

| Previous Process / Contact | Inputs | Description of Key Activities | Outputs | Subsequent Process / Contact | |

| Purchasing Process | wire, materials |

· create Production Setup Checklist and any required inspection forms · schedule production · setup machines and form wire |

· perform secondary operations as necessary · inspect product · perform equipment maintenance |

finished product | Shipping Process |

| Order Handling Process | customer drawings / specs | ||||

|

Related Procedures: · Quality Planning Procedure · Customer Prints Procedure |

· Production Control – Main Procedure · Production Control – Secondary Operations Procedure |

· Control of Nonconforming Product Procedure |

|||

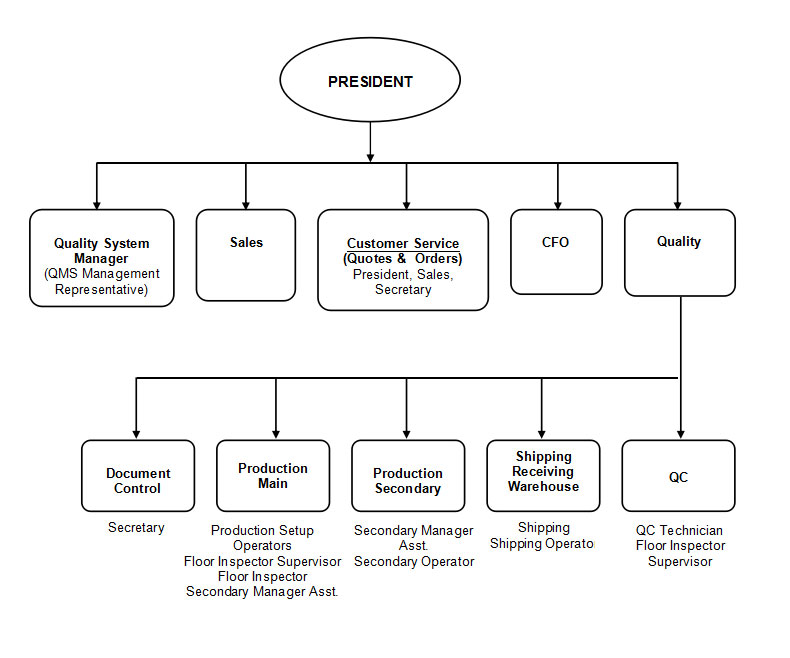

Organization Chart